Electrical safety audits thoroughly evaluate industrial and commercial facilities' electrical systems, focusing on adherence to strict standards. A core component is the arc flash hazard analysis, which assesses electric arc risks by examining equipment, wiring, and protective gear. This analysis guides strategic risk reduction strategies, like upgrading equipment, providing PPE, and enhancing worker training, thereby minimizing downtime and legal liabilities while prioritizing employee safety and regulatory compliance. Regular audits complement these efforts, ensuring continuous improvement in electrical safety infrastructure.

Electrical safety audits are vital for identifying and mitigating risks within industrial environments. This comprehensive overview explores the key components of a thorough audit process, emphasizing the critical role of Arc Flash Hazard Analysis (AFHA) in risk reduction. By understanding relevant regulations and standards, organizations can ensure electrical safety compliance.

Regular audits not only identify potential hazards like arc flash but also drive continuous improvement, enhancing workplace safety and operational efficiency across industries.

- Understanding Electrical Safety Audits: A Comprehensive Overview

- The Role of Arc Flash Hazard Analysis in Audit Process

- Identifying and Mitigating Arc Flash Risk Factors

- Ensuring Electrical Safety Compliance: Regulations and Standards

- Key Components of a Thorough Electrical Safety Audit

- Post-Audit Actions: Implementing Recommended Changes

- Benefits of Regular Electrical Safety Audits for Industries

Understanding Electrical Safety Audits: A Comprehensive Overview

Electrical safety audits are crucial assessments that help identify and mitigate risks associated with electrical systems within industrial or commercial settings. These comprehensive evaluations go beyond simple inspections, delving into every aspect of an organization’s electrical infrastructure. By conducting a thorough audit, businesses can ensure they adhere to stringent electrical safety compliance standards.

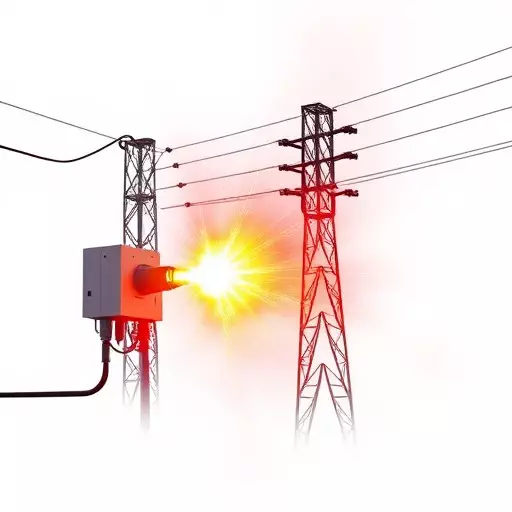

An essential component of these audits is the arc flash hazard analysis, which evaluates potential risks from electric arcs. This process involves meticulous examination of equipment, wiring, and protective gear to implement effective arc flash risk reduction strategies. Such measures are vital in minimizing accidents and protecting workers, as well as preventing costly downtime and legal liabilities resulting from electrical failures.

The Role of Arc Flash Hazard Analysis in Audit Process

Arc Flash Hazard Analysis plays a pivotal role in the electrical safety audit process by identifying and mitigating risks associated with potential arc flash events. This systematic evaluation involves assessing the likelihood and severity of an arc flash, considering factors such as equipment design, maintenance history, and work practices. By understanding these hazards, audits can focus on implementing effective arc flash risk reduction strategies, ensuring electrical safety compliance.

During an audit, professionals thoroughly examine electrical systems to pinpoint areas where arc flashes could occur most dangerously. This includes analyzing circuit protection devices, grounding systems, and personal protective equipment (PPE). The goal is not only to adhere to regulatory standards but also to create a safer work environment by minimizing the potential for severe injuries or property damage caused by arc flash events.

Identifying and Mitigating Arc Flash Risk Factors

Identifying and mitigating arc flash risk factors is a crucial component of electrical safety audits, as arc flash hazards are a significant concern in industrial settings. An arc flash hazard analysis involves thoroughly examining the electrical system to understand potential triggers and assess the associated risks. This includes evaluating the type and rating of protective devices, circuit configurations, and the proximity of personnel to live parts. By identifying these factors, facility managers can implement targeted strategies for arc flash risk reduction.

Effective mitigation measures may include upgrading outdated equipment, installing appropriate protective gear, enhancing training programs for workers, and implementing strict safety protocols. Ensuring electrical safety compliance not only minimizes the risk of severe injuries or fatalities but also helps businesses meet regulatory requirements. A proactive approach to arc flash hazard management contributes to a safer workplace environment and reduces downtime caused by accidents.

Ensuring Electrical Safety Compliance: Regulations and Standards

Ensuring electrical safety compliance is non-negotiable in any industrial or commercial setting. This involves adhering to stringent regulations and standards set forth by governing bodies, such as OSHA (Occupational Safety and Health Administration) or local electrical codes. One critical aspect of this is conducting thorough arc flash hazard analyses. These assessments identify potential risks associated with electrical equipment, including the intensity of a potential arc flash and its associated hazards.

By understanding these risks, organizations can implement effective strategies for arc flash risk reduction. This includes proper labeling, personal protective equipment (PPE) requirements, and ensuring safe work practices are in place. Regular electrical safety audits play a pivotal role in this process by evaluating compliance against established standards, identifying gaps, and recommending necessary improvements to safeguard employees and prevent accidents related to electrical hazards.

Key Components of a Thorough Electrical Safety Audit

A thorough electrical safety audit involves several critical components that ensure the protection of both personnel and assets. One of the primary aspects is conducting a comprehensive arc flash hazard analysis, which identifies potential risks associated with electric arcs and their impact on workers and equipment. This analysis takes into account factors like electrical systems, work practices, and protective gear to mitigate the hazards effectively.

Additionally, an effective audit focuses on electrical safety compliance, ensuring that installations adhere to relevant codes, standards, and best practices. This includes examining grounding systems, circuit protection devices, and wiring configurations to verify their suitability for reducing arc flash risks. By implementing strategies for arc flash risk reduction, such as proper labeling, training, and equipment upgrades, facilities can significantly enhance their overall electrical safety compliance.

Post-Audit Actions: Implementing Recommended Changes

After a thorough electrical safety audit, the next critical step is to act on the findings and recommended changes. Implementing the suggested actions ensures that any identified hazards are mitigated and electrical safety compliance is enhanced. This process involves prioritizing and planning the necessary updates to electrical systems, equipment, and procedures based on the severity of risks.

For instance, an arc flash hazard analysis may reveal areas where potential dangers can be reduced through simple modifications like improved labeling, additional protective gear provisions, or enhanced training for personnel. Implementing these changes not only reduces the risk of arc flash but also demonstrates a commitment to electrical safety across the organization, fostering a culture of compliance and awareness.

Benefits of Regular Electrical Safety Audits for Industries

Regular electrical safety audits are a game-changer for industries, offering numerous benefits that extend far beyond simple compliance with regulations. By conducting thorough assessments, companies can identify potential hazards like arc flash risks and take proactive measures to mitigate them. These audits provide a systematic approach to managing electrical safety, ensuring that equipment is maintained, and systems are updated to the latest standards.

Through regular reviews, businesses gain valuable insights into their electrical infrastructure. This includes identifying outdated components, faulty wiring, or improper installations, all of which contribute to increased hazards. By addressing these issues promptly, companies can prevent accidents, reduce downtime due to emergencies, and ultimately save lives. Moreover, a culture of proactive safety measures fosters a more secure environment for employees, enhancing productivity and peace of mind.